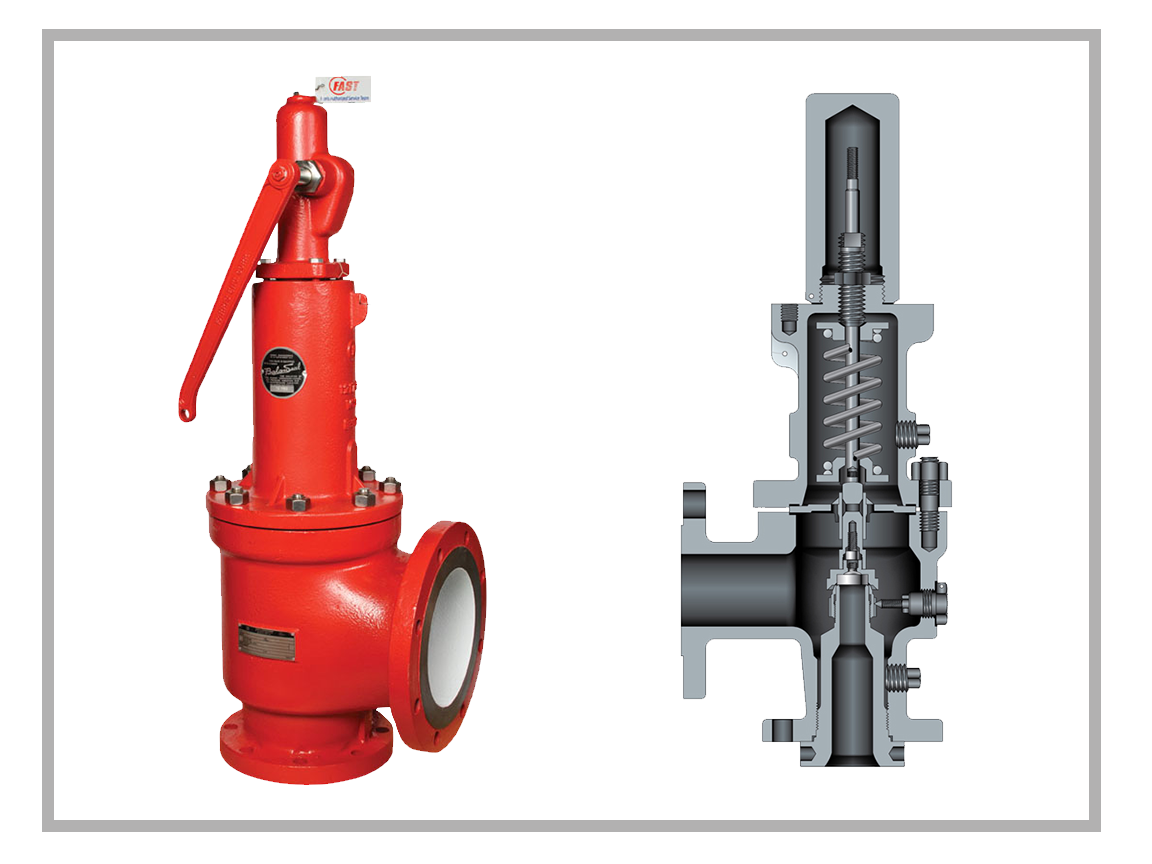

Process Valves / Series 2600/2600L

Conforms to API 526

Full Nozzle Design

Integral Cast Flanges

Metal Seat with optional o-ring

Balanced Bellows option

Open Bonnet and Lever Assemblies option

Adjustable Blowdown

2600L – Multiple Service Single Trim Design option

Size 1” x 2” to 20” x 24”

Orifice Areas D (0.15in2) to Z (176.7 in2)

Set Pressure Ranges 15 to 6000 psig (1.0 to 413 barg)

Temperature Ranges -320 to 1500°F (-195 to 815°C)

Flange Classes 150# – 2500#

Suitable for Air, Gas, Vapor, Steam & Liquid Service

Materials of Construction Carbon Steel

Stainless Steel

Low/High Temperature Alloy Steels

Monel

Hastelloy C

NACE Compliant Materials

Duplex

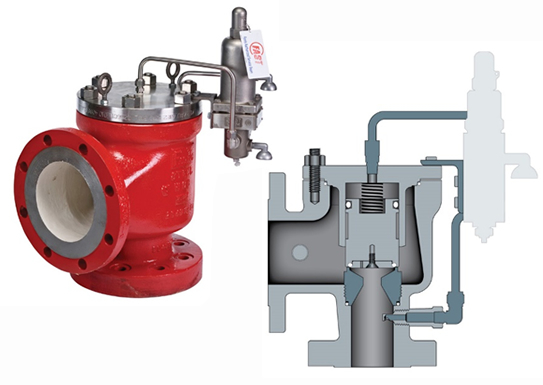

Series 3800/3800L

Conforms to API 526

Snap Acting and Modulating Control Actuation

Semi and Full Port Nozzle Design

Typical Blowdown of 3-6%

General Specifications

Size 1” x 2” to 12” x 16”

API Orifice Areas D (0.15 sq2) to T (26.0 sq2)

Non-API Orifice Areas A, 1-8 (45.66 sq2)

Set Pressure Ranges 15 to 6170 psig (1.0 to 425 barg)

Temperature Ranges -320 to 500°F (-195 to 260°C)

Flange Classes 150# – 2500#

Suitable for Air, Gas, Vapor, Steam & Liquid Service

Materials of Construction Carbon Steel: Stainless Steel-Low / High

Temperature Alloy Steels – Monel — Hastelloy C – Duplex — NACE Compliant Materials

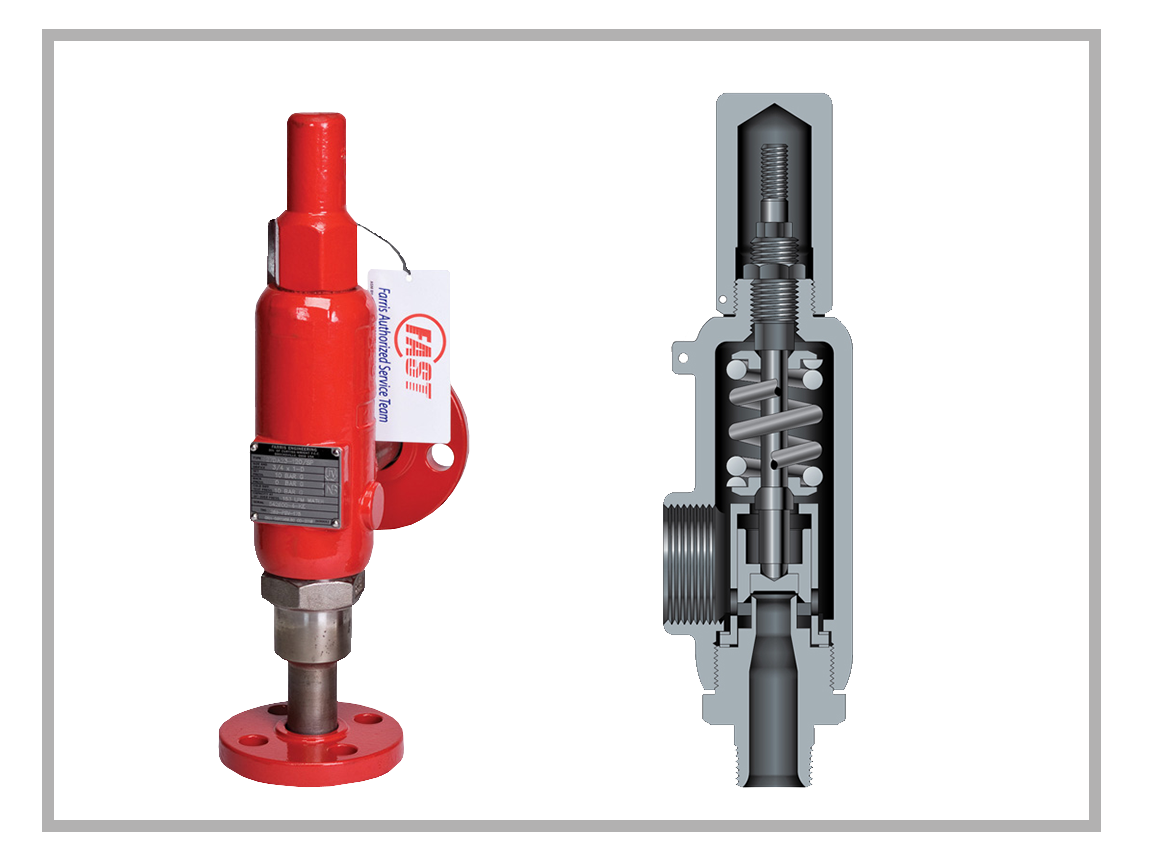

Series 2700

Metal Seat with optional o-ring

Balanced design option

Flanged option

Optional welding nipple and sanitary connections

Size 1/2” x 1” to 1-1/2” x 2-1/2”

Orifice Areas C (0.068 sq2) to G Orifice (0.573 sq2)

Set Pressure Ranges 15 to 6500 psig (1.0 to 413 barg)

Temperature Ranges -320 to 750°F (-195 to 399°C)

Flange Classes 150# – 2500#

Suitable for Air, Gas, Vapor, Steam & Liquid Service

Materials of Construction: Carbon Steel - Stainless Steel - Low / High

Temperature Alloy Steels – Monel – Hastelloy C – Duplex – NACE Compliant Materials

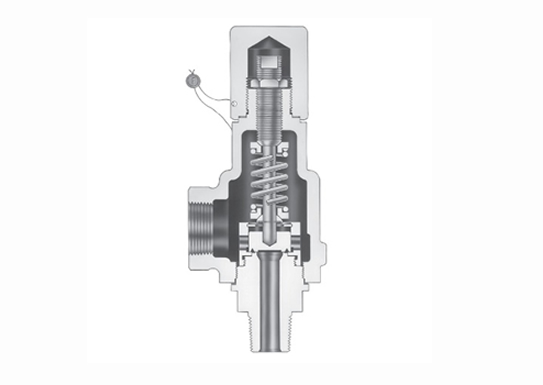

Series 1890

Threaded Steel PRV

ASME/NB Certified – Air, Steam & Water

Full Bore Nozzle Design

Size: 1/2” x 1” & 3/4” x 1”

Orifice Areas: .077 (liquid).089 (vapor) square inches

Set Pressure Ranges: 15 to 800 psig

Temperature Ranges: -20 to 750°F

Suitable for: Air, Steam, Gas & Water

Materials of Construction: Carbon Steel Bonnet - Stainless Steel Body & Trim

Pressure Relief Valve / Series 2400

ASME Section VIII

Direct Spring Loaded

Soft Seat Design

External Blowdown Control

Full Lift at Set Pressure

Size: 1/2” x 3/4” to 1” x 1”

Orifice Areas: B (0.049 in2) to E (0.196 in2)

Set Pressure Ranges: 20 to 2,000 psig (1.38 to 137.9 barg)

Seat Materials: Elastomer, Plastic

Suitable for: Air, Gas, Vapor

Materials of Construction: Carbon Steel - Stainless Steel - Brass/Bronze

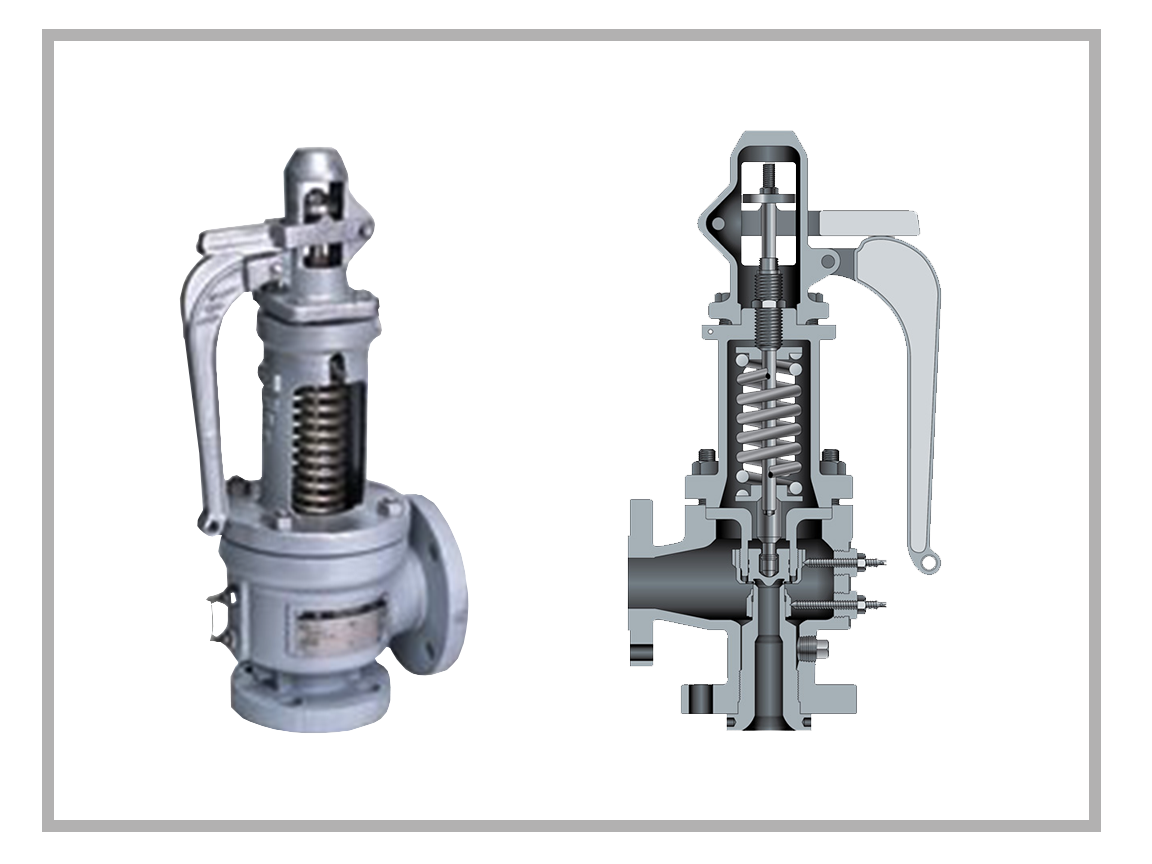

Steam Safety Valve / Series 6400

Flanged Spring-Loaded Boiler Safety Valve

Available in closed bonnet or exposed spring versions

Hardened conical disc for extended seat life

Full nozzle design

Size 1” x 2” to 4” x 6”

Orifice Areas D (0.150 sq2) to P Orifice (7.087 sq2)

Set Pressure Ranges 15 to 1500 psig (1.0 to 103barg)

Temperature Ranges -20 to 1000°F (-29 to 538°C)

Flange Classes 150# – 1500#

Materials of Construction: Carbon Steel - Stainless Steel - Chrome-Moly

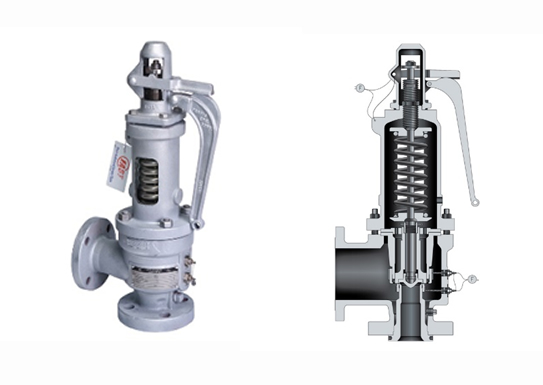

Series 4200

Flanged Spring-Loaded Boiler Safety Valve

Full nozzle design

Open bonnet design

One-piece guide

Low stem bearing point

Temperature equalizing disc

Heavy stainless-steel lock screw studs

Test Gag Optional

Size 1” x 1/4” x 1-1/2” to 6” x 8”

Orifice Areas F (0.316 sq2) to Q Orifice (11.39 sq2)

Set Pressure Ranges 15 to 1000 psig (1.0 to 68.9 barg)

Temperature Ranges -20 to 1000°F (538°C)

Flange Classes 150# – 600#

Materials of Construction: Carbon Steel - Stainless Steel - Low / High

Temperature Alloy Steels – Chrome-Moly

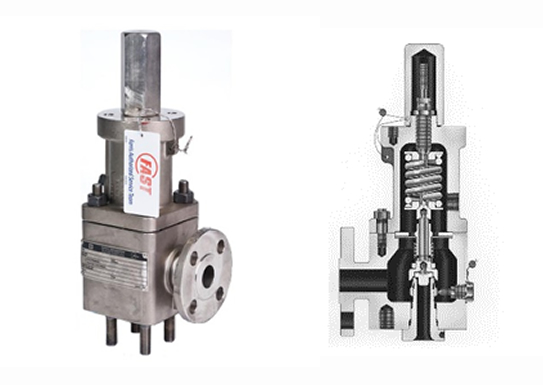

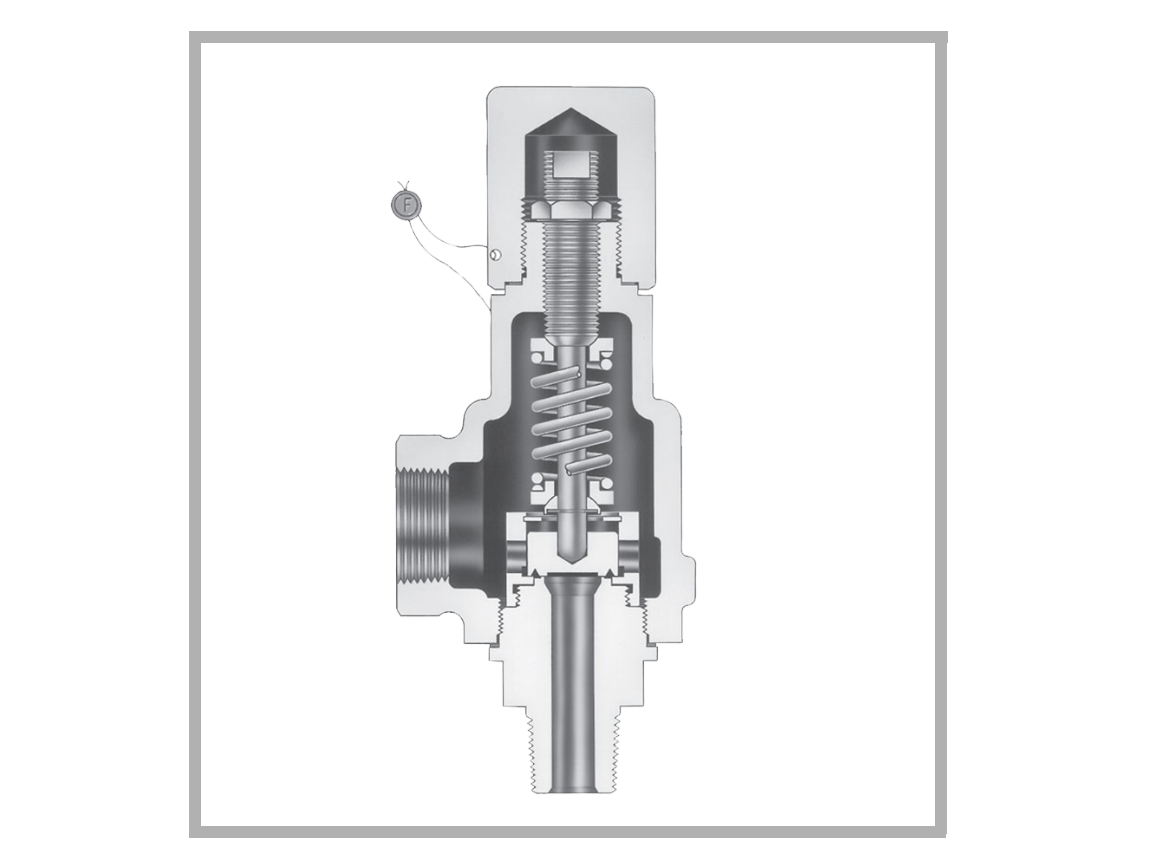

Series 4700

Balanced bellows design option

Metal seat with optional o-ring

Full nozzle construction

General Specifications

Size: 1/2” x 3/4” & 3/4” x 1” & 1”x1”

Orifice Areas: B (0.028 sq2) to E (0.225 sq2)

Set Pressure Ranges: 15 to 6000 psig (1.0 to 413 barg)

Temperature Ranges: -450 to 1000°F (-268 to 299°C)

Flange Classes: 150# – 1500#

Materials of Construction: Carbon or Stainless - Steel Body & Bonnet -

Stainless Steel Trim – NACE – Hastelloy – Monel

Smart Prv

2600 Series Pressure Relief Valve Equipped with a Fisher 4320 Wireless Position Monitor

WirelessHART Protocol

Integrates into plants with existing Emerson Wireless Infrastructure

Orifice Sizes D through U

Retrofits available for installed 2600 Series valves

Farris SmartPRV technology is a simple, powerful solution to improve your ability to monitor critical safety valve and their effects on plant performance.

Overpressure events are unpredictable, can go unnoticed and consequently can be difficult to estimate.

Using the SmartPRV system, facilities are not able to record over pressure events.

SmartPRV provides

Equipped plants with the ability to track and monitor valves in real time

Provides immediate feedback during an overpressure event

Feedback includes the time and duration of the overpressure event

Allowing plants to more accurately estimate releases

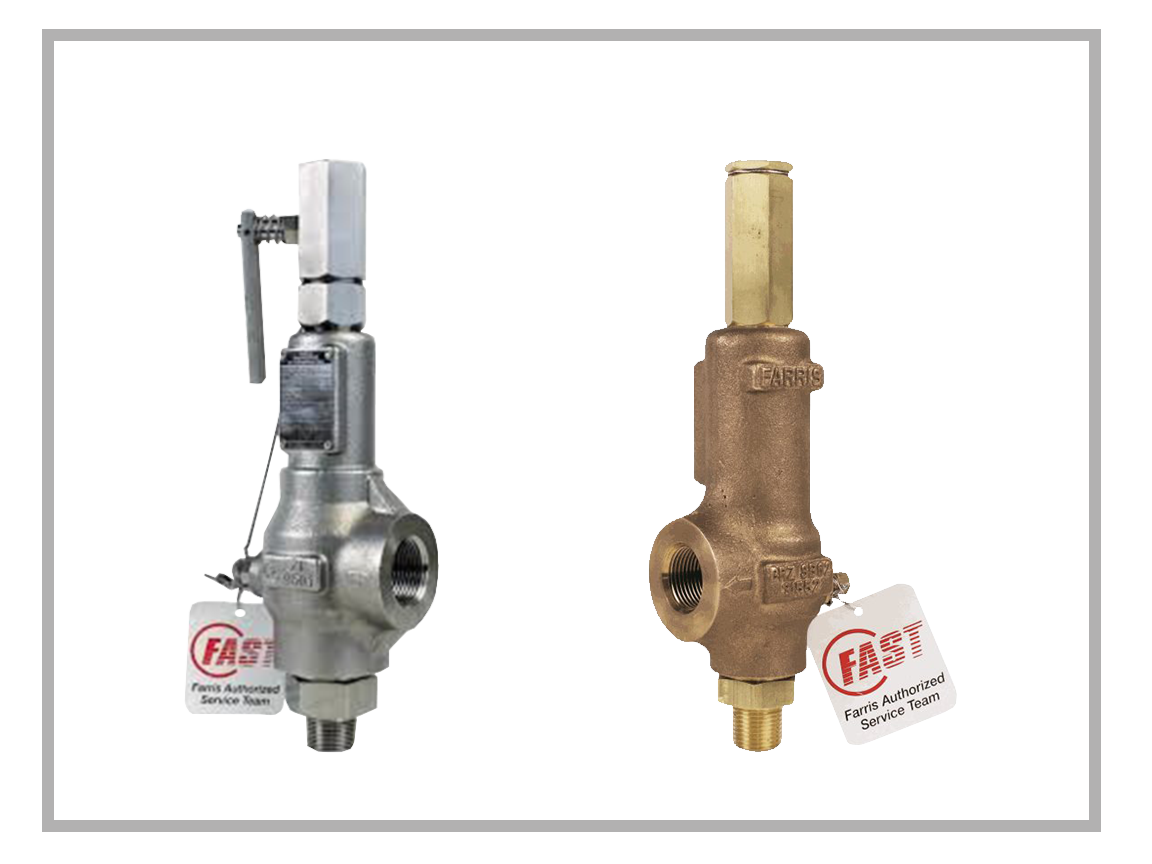

Specialty Valves / Series 1890

Threaded Steel PRV

ASME/NB Certified – Air, Steam & Water

Full Bore Nozzle Design

Size: 1/2” x 1” & 3/4” x 1”

Orifice Areas: .077 (liquid).089 (vapor) square inches

Set Pressure Ranges: 15 to 800 psig

Suitable for: Air, Steam, Gas & Water

Materials of Construction: Carbon Steel Bonnet - Stainless Steel Body & Trim

Series 1890

Threaded Brass/Bronze PRV

Full Bore Nozzle Design

Size: 1/2” x 3/4” & 3/4” x 3/4”

Orifice Areas: 0.110

Set Pressure Ranges: 15 to 300 psig

Temperature Ranges: -320 to 400°F

Suitable for: Air, Steam & Water

Materials of Construction: Bronze Bonnet - Brass Body & Trim y