HITACHI Gas Compressor

These compressors truly show our advanced technology and extensive experience.

Centrifugal compressors for process use are the heart of various types of plants that require high reliability.

Also, customers throughout the world trust us to provide efficiency compressors that use high-efficiency impellers that we’ve developed.

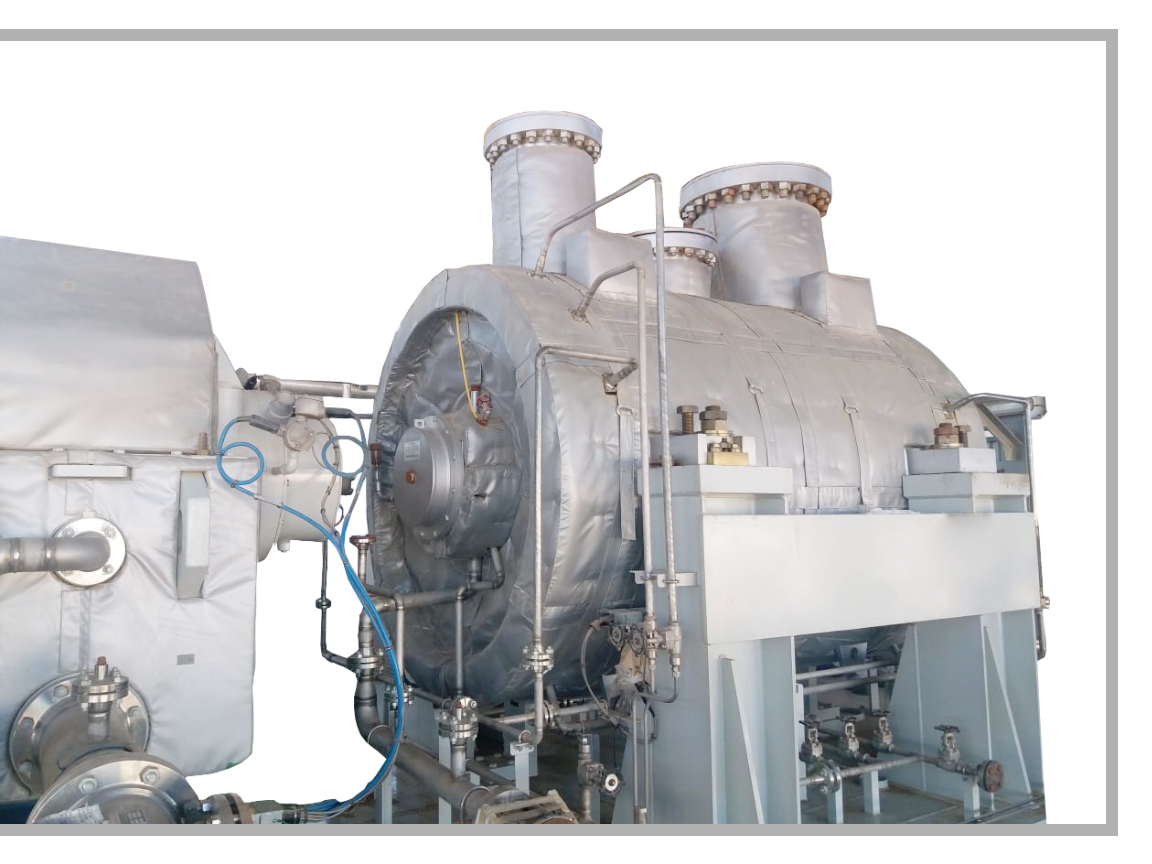

Vertically split (barrel-shaped BCH) compressors are used for hydrogen and other light gases and applications with a high pressure of about 4-35 MPa, and are capable of high-speed stable operation at rotation speeds of up to about 15,000 revolutions per minute.

Features - High Reliability

We have accumulated many achievements by adding new technologies to the technologies we have cultivated over many years. Since the 1970s we have adopted a unique automatic computer design system that has proven to be highly reliable.

High efficiency

Our high-efficiency 3D impeller has been used in many countries throughout the world.

Our compressors have high efficiency at the top level in the world, and are also compact and lightweight.

Robust Design and outstanding technology

In addition to tilting pad bearings, we also have the technology for oil-free magnetic bearings.

We use various types of analysis techniques, including high-pressure fluid vibration analysis technology.

We aim for more advanced products through the use of an integrated system of design and manufacturing using 3D CAD.

Main applications

These are used for many applications in oil refineries and desulfurization plants, synthetic gas plants, various types of natural gas plants, chemical plants, etc.

Compressor

A compressor is machinery that compresses gases such as air and gas. Compressors are used in various places and for various applications in society, and modern society cannot function without compressors. We have an extensive product line-up to satisfy various needs, ranging from the large centrifugal compressors for process use that form the heart of petrochemical plants, chemical plants, and natural gas plants, as well as general-purpose compressors used in automotive applications, electronics, IT, food processing, steel, and other plant lines. We supply products not only in Japan, but also overseas, based on our long experience and advanced technology.

Product/Solution Centrifugal Compressors

Reciprocating Compressors/Screw Compressors/After-Sales Service

Hitachi provides service of solutions to customer’s problems by using abundant experience, knowledge and recent technologies. Our solutions make it possible for customers to do an optimum economical operation, extend life cycle of machines, modernize, upgrade and renew aging machines. Centrifugal & Reciprocating Compressors

Screw Compressors

Small Turbo Compressors

With about a history and extensive experience in the field of centrifugal compressors, we have used the latest CFD(Computational Fluid Dynamics) analysis technology to produce a high-efficiency, low-maintenance, compact turbo-type standard air compressor. We also satisfy our customers’ needs with the new specification with environmentally-friendly high-quality air, low vibrations, low noise, and excellent ease of operation.

Compressor type by application

Centrifugal compressors for process use are the heart of various types of plant that require high reliability. Also, customers throughout the world trust us to provide high efficiency compressors that use high-efficiency impellers that we’ve developed. Please take a look at our compressors by application.

Project Examples

Japan

Overseas

Hitachi Compressor Brochures

Saving Energy & Operating Cost

Hitachi enhances energy saving activities and environmental measures

Enhancing energy saving activities and environmental measures has been required by amendment of Japan’s Energy Conservation Act in April 1999. Hitachi has responded to this need by providing our customers with several diagnosis and technologies developed by Hitachi. Also Hitachi is actively working to improve environmental preservation and recycling activities.

General description of Saving Energy & Saving Operating Cost for rotating equipments

Horizontally Split Process Centrifugal Compressors (MCH)

These compressors truly show our advanced technology and extensive experience.

Centrifugal compressors for process use are the heart of various types of plants that require high reliability. Also, customers throughout the world trust us to provide the efficiency compressors that use high-efficiency impellers that we’ve developed. The MCH-type compressor, which is suitable for pressures in the range about 4-5 MPa, has a horizontally split casing and a sturdy casing structure, so it is easy to do maintenance inside the casing.

Features / High Reliability

We have a long history arising from our technology cultivated over many years combined with new technology.

Since the 1970s we have adopted a unique automatic computer design system that has proven to be highly reliable.

High Efficiency

Our high-efficiency 3D impeller has been used in many countries throughout the world.

Our compressors have high efficiency at the top level in the world, and are also compact and lightweight.

Easy-to-maintain structure and excellent technology

Our analysis technology for the shaft system and other excellent technologies are highly reliable.

The structure within the casing takes maintenance into consideration, including the bearings and seals.

Main Applications

These are used in ethylene plants, ammonia plants, oil refineries, and chemical plants.